roughing end mill feeds and speeds

Tipped End Mill 13642 48-005 na na 1 na na na 12 Straight V Carbide Tipped End Mill 13564 48-072 na na 2 na na na 14 Upcut Carbide End. Speeds and feeds speeds and feeds for grooving tools material plastic magnesium aluminum copper brass bronze cast iron steel titanium stainless nickel monel inconel waspaloy hastelloy type teflon nylon phenolic glass filled azamezzehk 2021 thru 6061 101-707 834-978 gray ductile malleable 1005-1029 1030-1055 1060-1095 10l45-10l50 12l13-12l15.

7 Tips For Choosing The Right End Mill For The Job M M Sales Equipment

This will adjust the feedrate if less than the tool rad.

. Speeds Feeds Solid Carbide High Performance End Mills. Order Your Industrial Tools At Grizzly. Radial Side Depth of Cut.

Normally a 20 reduction in effective horsepower is used. Speed And Feed Calculators Ball Mill Finish Calculator Part Spacing Calculator G And M Code Characters Standard End Mill Sizes Standard Drill Sizes Drill And Counterbore Sizes. We have broken these recommendations down into material categories so you can make better decisions with how to.

Now we need Feeds and Speeds. PROMAX Premium Feeds Speeds DESIGN-RITE XL Feeds Speeds. Cart Shopping Cart Toggle navigation.

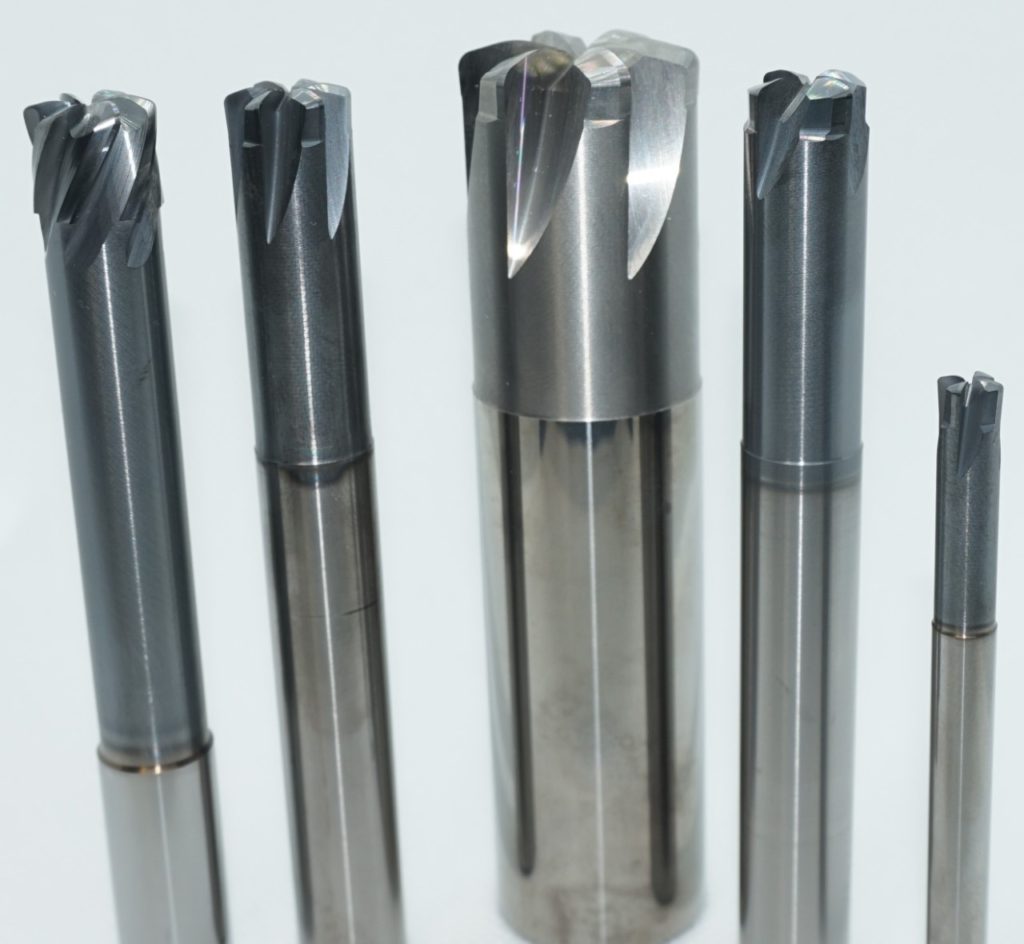

Tool Rigidity and good chip discharge the most suitable for high. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions. END MILLS RPM PER TOOTH RPM PER TOOTH RPM PER TOOTH RPM PER TOOTH RPM PER TOOTH RPM PER TOOTH RPM PER TOOTH RPM PER TOOTH RPM PER TOOTH 116-----1222-24440002-0005.

Unparalleled Performance Every Time. Chip load x Number of flutes. Lets work through an example that shows the strengths of plunge milling.

Now we need feeds and speeds. Surface Feet per Minute - SFM Feed Rate Inch per Tooth - IPT Radial Width of Cut WOC ae d1 End Mill Diameter Multiply IPT x this factor based on WOC Free Machining Low Carbon Steels 1006 1008 1015 1018 1020 1022 1025 1117 1140 1141 11L08 11L14 1213 12L13 12L14 1215 1330 GREEN up to 28 HRc 1700 1350 750 425 425 0005 0042. TiN Coated End Mills.

Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill. End Mill Speed Feed HSS M42 Cobalt. Speed and feeds for high speed Steel and Cobalt End Mills.

Roughing End Mills - Cobalt and High Speed Steel. We Are The Purveyors Of Fine Machinery. Ad Solid Carbide Cutting Tools Designed For Closer Tolerances A Longer Lifespan.

Please contact our very knowledgeable Technical Department at 800-878-0502. When using long and extra-long end mills reduce feed per tooth 50. I am side milling the required depth is 15 inches.

Designed for high speed roughing and finishing of complex contoured shapes in hardened materials. Suppose we are handed the task of roughing out a pocket that has 18 corner radii which dictates and endmill no larger than 14 in diameter. MPM represents the rate of the surface of the cutter passes over the.

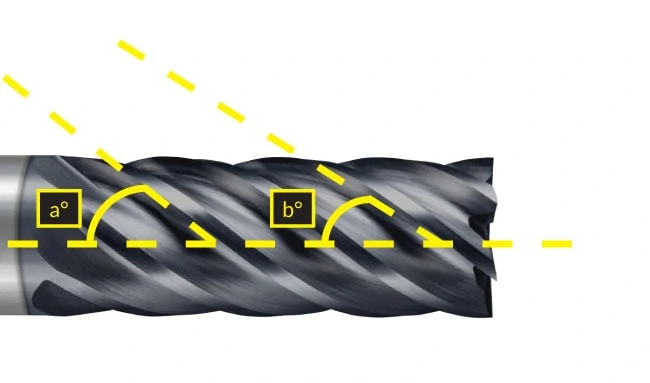

The Turbo Carb end mill is made of an application specific carbide to improve wear resistance and toughness in demanding applications. Higher range of recommended surface speeds should be used For Greater Radial Depths-of-Cut. While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEMHEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC.

On Steels 45 HRC on Roughing use Coolant on Finishing Run Dry TiCN add 40 on. Increase the cutting speed feed rate until the quality of the parts finish starts to decrease or the part is starting to move from hold downs. This spreads wear evenly across the cutting edge dissipates heat and reduces the chance of tool failure.

Lets work through an example that shows the strengths of Plunge Milling. Increase speed by 25-50 TAIN Coated End Mills. Feed InchTooth End Mill Diameter 18 316 14 38 12 58 34 1 Recommendation for Coated Tools.

Meters Per Minute MPM The cutting speed of the end mill. We are here for you. How to use this calculator.

This system is used in all countries that use the Metric system. They may be increased or decreased depending on machine condition depth of cut finish required coolant etc. PREMIUM COBALT MILL SPEED FEED Multi-Flute - Side Cutting - Roughing - HSS-C08 End Mills CHARTS Aluminum Aluminum Alloys Material Hardness Diameter 14 516 38 12 58 1116 78 1-18 1-14 1-38 1-34 Carbon Steels Alloy Steels Tool Steels Carbon Steels Alloy Steels Tool Steels.

Ad Buy Grizzly Today. Roughing End Mills - Cobalt and High Speed Steel. Made In The USA Commercial Cutting Tools End Mills.

All speed and feed data are suggested starting points. My initial numbers are 15 axial depth of cut 116 radial depth of cut speed 500 RPM and feed of 66 ipm. The material is 4140A the set-up is not an issue plenty to grab by in the vice.

Increase speed by 25 TiCN Coated End Mills. Likewise we are here to assist you in determining the correct feeds and speeds starting points based on roughing end mills or finishing end mills you are using. Our G-Wizard Feeds and Speeds Calculator has special features to help with plunge milling.

In the metric system the feed rate of the cutter can be calculated for each revolution of the cutter. Our G-Wizard Feeds and Speeds Calculator has special features to help with Plunge Milling. I am using a HSS 34 diameter x 1-58 length roughing endmill machine has 20HP.

Choose a type of operation drilling reaming boring counterboring face milling slab millingside milling end milling or turning select your stock material choose a material for the tool high-speed steel or carbide input the quantity of teeth for the tool and the diameter of the workpiececutter. Milling Speeds and Feeds Charts The most important aspect of milling with carbide end mills is to run the tool at the proper rpm and feed rate. ROUGHING END MILLS Speed and Feed Data Chip Load per Tooth Material SFM 18 14 12 1 Aluminum Alloys 125-250 0010 0020 0025 0030 Magnesium 125-250 0010 0020 0025.

Increase speed by 50-75. End Mill Speed Feed Calculator. The high-performance S-Gash geometry on the ball improves shearing while reducing the load.

All recommendations should be considered only as a starting point with possible variations to achieve optimum results. Suppose we are handed the task of roughing out a pocket that has 18-inche corner radii which dictates and end mill no larger than 14-inch in diameter. Then decrease speed by 10.

55 - 65 HRC CNC Cutting Tools Roughing End Mill With Dia 6 - 20 mm Description Layers with high heat resistance can be high-speed processing. Now we need Feeds and Speeds.

Speed Feed Recs Melin Tool Company

Accusize Industrial Tools 3 4 Inch M42 8 Cobalt Tialn Roughing End Mill 3 4 In Shk Dia 1 5 8 In Flute Length Fine Tooth 1104 0034 Amazon Ca Industrial Scientific

Speed Feed Recs Melin Tool Company

End Mills The Essential Beginners Guide

Freud 87 308 3 Piece Fine Detail Cnc Router Bit Set Cnc Router Bits Cnc Router Router Bit Set

Solid Carbide End Mills Haimer

What To Know When Selecting An End Mill End Mill The Selection Machining Process

Multiple Uses Of Chamfers Multiple Cost Saving Canning

Speed Feed Recs Melin Tool Company

Speed Feed Recs Melin Tool Company

End Mills Contour360 High Performance End Mill Manufacturers

8 Ways You Re Killing Your End Mill In The Loupe

Speed Feed Recs Melin Tool Company

Speed Feed Recs Melin Tool Company

Speed And Feeds For High Speed Steel And Cobalt End Mills

4 6 Flute High Feed End Mills Epic Tool